Anodizing aluminum sassamagani ne na gama gari wanda ke haɓaka juriyar lalata su, karko, da ƙayatarwa.A cikin takarda karfe da CNC machining samarwa yi, akwai kuri'a na aluminum sassa bukatar anodized, duka biyualuminum sheet karfe sassakumaaluminum CNC machined sassa. Kuma wani lokacin abokin ciniki yana buƙatar sassan da aka gama cikakke ba tare da wani lahani ba. Ba za su iya karɓar wuraren tuntuɓar da ake iya gani a fili ba inda ba tare da wani abin rufe fuska ba.

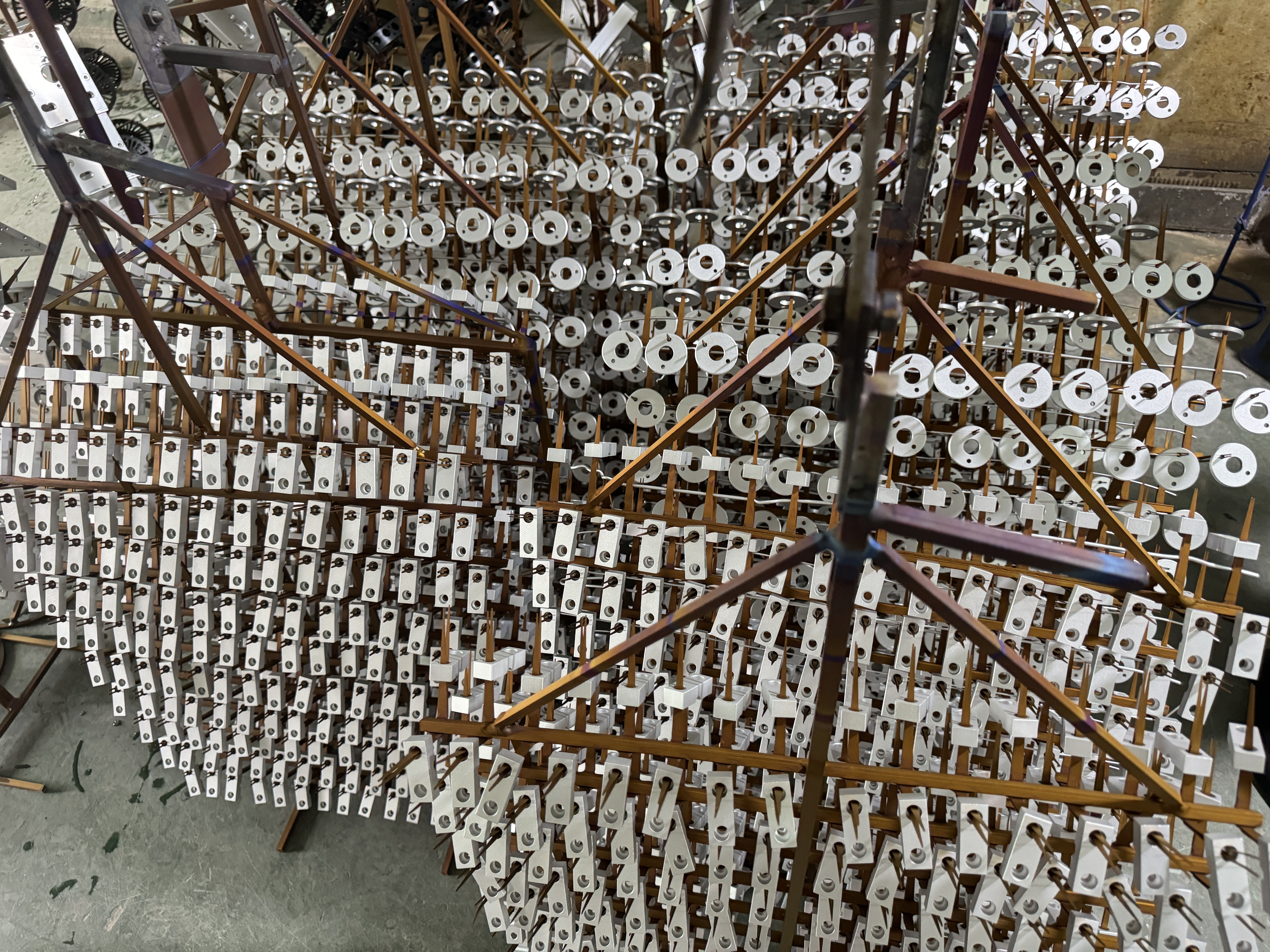

Duk da haka, a lokacin daaluminum anodizingtsari, wuraren tuntuɓar ko wuraren da ɓangaren ke shiga cikin hulɗar kai tsaye tare da madaidaicin rataye ko shiryayye ba za a iya zama anodized yadda ya kamata ba saboda rashin samun damar yin amfani da maganin anodizing. Wannan ƙayyadaddun ya samo asali ne daga yanayin tsari na anodizing da kuma buƙatar haɗin da ba a rufe ba tsakanin sashi da kuma maganin anodizing don cimma daidaituwa da daidaiton yanayin anodized.

Theanodizing tsariya haɗa da nutsar da sassan aluminum a cikin bayani na electrolyte da kuma wuce wutar lantarki ta hanyar maganin, samar da oxide Layer a saman aluminum. Wannan Layer oxide yana ba da fa'idodi na musamman naaluminum anodized, irin su haɓaka juriya na lalata, ingantaccen ƙarfi, da ikon karɓar launin rini.

Koyaya, lokacin da aka lalata sassan ta amfani da madaidaicin rataye ko tara, wuraren tuntuɓar inda sashin ya shiga hulɗar kai tsaye tare da sashin ana kiyaye shi daga maganin anodizing.. Sabili da haka, waɗannan wuraren tuntuɓar ba sa aiwatar da tsarin anodizing iri ɗaya kamar sauran ɓangaren, wanda ke haifar da rataye aibobi ko alamomi bayan anodization.

Don magance wannan matsala da rage girman hangen nesa na wuraren dakatarwa, dole ne a yi la'akari da hankali ga ƙira da sanya ɓangarorin dakatarwa da kuma dabarun gamawa bayan anodizing.Zaɓin ɓangarorin dakatarwa tare da ƙaramin yanki na ƙasa da kuma tsara dabaru na iya taimakawa rage tasirin wuraren hulɗa akan bayyanar ƙarshe na ɓangaren anodized. Bugu da kari, bayan-anodization matakai kamar haske sanding, polishing, ko gida anodizing gyare-gyare za a iya amfani da su rage ganuwa na rataye maki da kuma cimma mafi uniform anodized surface gama.

Dalilin da ya sa ba za a iya zama anodized wuraren tuntuɓar a yayin aikin anodizing na aluminum ba saboda toshewar jiki wanda ke haifar da shingen rataye ko shiryayye. Ta hanyar aiwatar da ƙira mai tunani da dabarun ƙarewa, masana'antun za su iya rage tasirin abubuwan tuntuɓar a kan ingancin gaba ɗaya da bayyanar sassan aluminum anodized.

Manufar wannan labarin ita ce bincika zaɓin ɓangarorin dakatarwa na anodized, dabarun rage rataye, da dabaru don tabbatar da cikakkiyar farfajiyar anodized.

Zaɓi sashin dakatarwa daidai:

Lokacin zabar sashin dakatarwar anodized, yana da mahimmanci a yi la'akari da waɗannan abubuwan:

1. Daidaituwar kayan aiki: Tabbatar cewa an yi shingen dakatarwa daga wani abu wanda ya dace da tsarin anodizing, kamar titanium ko aluminum. Wannan yana hana duk wani mummunan halayen da zai iya rinjayar ingancin yanayin anodized.

2. Zane da Geometry:An zaɓi ƙirar ɓangarorin dakatarwa don rage wuraren hulɗa tare da ɓangaren don rage haɗarin barin alamomin bayyane. Yi la'akari da yin amfani da santsi tare da santsi, gefuna masu zagaye da ƙaramin yanki don yin hulɗa da ɓangaren.

3. Juriyar zafi:Anodizing ya ƙunshi yanayin zafi mai yawa, don haka sashin dakatarwa dole ne ya iya jure zafi ba tare da yaƙe-yaƙe ko naƙasa ba.

Rage wuraren ratayewa:

Don rage abin da ya faru na rataye rataye akan sassan aluminum, ana iya amfani da dabaru masu zuwa:

1. Matsayin Dabaru: A hankali sanya ɓangarorin dakatarwa a ɓangaren don tabbatar da cewa duk alamun da aka samar suna cikin wuraren da ba a san su ba ko kuma ana iya ɓoye su cikin sauƙi yayin haɗuwa na gaba ko matakan gamawa. Hakanan yana buƙatar yin hankali yayin ɗaukar sassan daga maƙallan don kare saman sassan.

2. Masking: Yi amfani da dabarun rufe fuska don rufe ko kare filaye masu mahimmanci ko wuraren da wuraren rataye na iya faruwa. Wannan na iya haɗawa da amfani da kaset na musamman, matosai ko sutura don kare takamaiman wurare daga tuntuɓar sashin dakatarwa.

3. Shirye-shiryen Surface: Kafin anodizing, yi la'akari da yin amfani da jiyya na ƙasa ko jiyya don taimakawa ɓoye ko haɗa duk wasu abubuwan da suka rage a rataye a cikin yanayin gaba ɗaya.

Tabbatar da cikawar anodized:

Bayan anodizing, dole ne a duba sashin don duk sauran wuraren dakatarwa da ɗaukar matakin gyara kamar yadda ya cancanta. Wannan na iya ƙunsar dabarun sarrafa bayan aiki kamar yashi haske, goge goge ko gyare-gyaren anodizing na gida don kawar da ko rage ganuwa na kowane lahani.

A taƙaice, cimma ƙarshen anodized maras kyau akan sassan aluminum tare da kafaffen madaidaicin yana buƙatar yin la'akari da zaɓin sashi, tsara dabaru, da duban bayan anodization da hanyoyin gyarawa. Ta hanyar aiwatar da waɗannan ayyukan, masana'antun na iya rage kasancewar wuraren rataye da tabbatar da cewa sassan anodized sun hadu da ingantacciyar inganci da ƙa'idodi.

Lokacin aikawa: Mayu-20-2024