Ana amfani da wannan sabis ɗin sau da yawa don ƙirƙirar tsari, sassa, da sassa don masana'antu daban-daban, gami da kera motoci, sararin samaniya, likitanci, da gini.Za'a iya amfani da waldawar ƙarfe da haɗin gwiwa don ƙirƙirar samfuran kowane girman da rikitarwa.Masu sana'a waɗanda suka ƙware a cikin wannan sana'a suna amfani da kayan aikin walda masu inganci da dabaru don tabbatar da ƙarfin walƙiya mai ɗorewa wanda ya dace da ƙayyadaddun abokin ciniki.Suna kuma la'akari da nau'in ƙarfe da ake amfani da su da kuma yanayin da za a yi amfani da shi.

Ayyukan Ƙarfe na Sheet:Yanke,Lankwasawa ko Ƙarfafawa, TaɓakoRiveting,Walda kumaMajalisa.

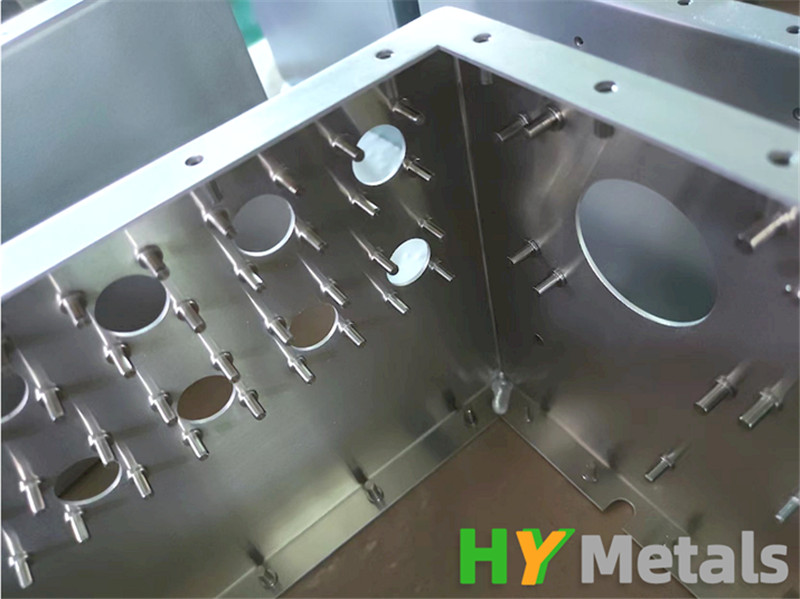

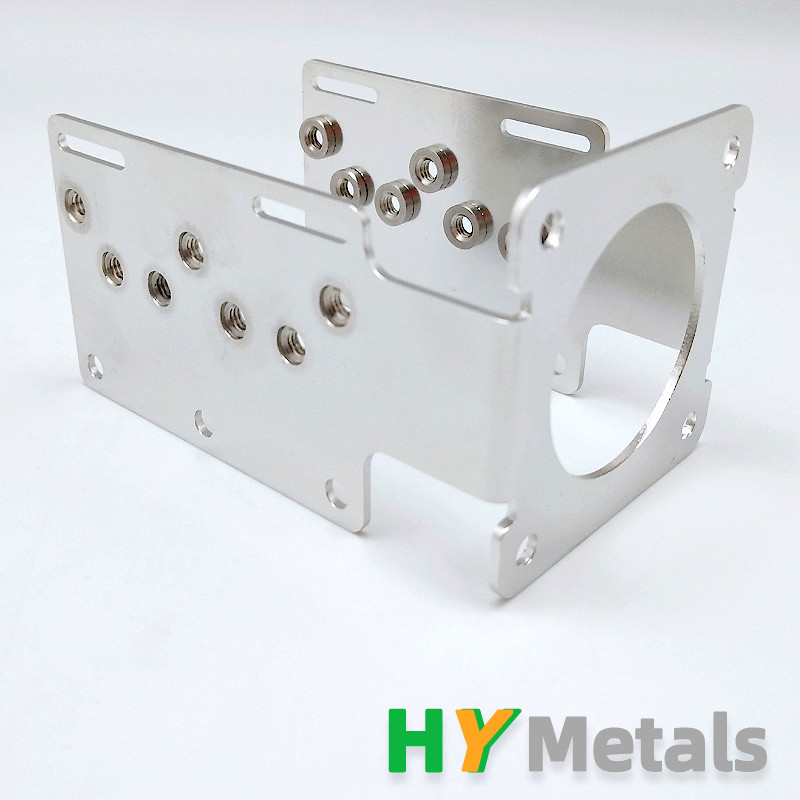

Sheet karfe taro ne tsari bayan yankan da lankwasawa, wani lokacin shi ne bayan shafi tsari.Yawancin lokaci muna harhada sassa ta hanyar riveting, walda, latsa dacewa da taɓawa don murƙushe su tare.

Tapping da Riveting

Zaren suna taka muhimmiyar rawa a cikin majalisai.Akwai manyan hanyoyi guda uku don samun zaren: Tapping, riveting, shigar coils.

1.Tzaren apping

Tapping wani tsari ne na yin zaren a cikin ramukan don sassan ƙarfe na takarda ko sassan injinan CNC tare da injin famfo da kayan aikin famfo.Ana amfani dashi ko'ina akan wasu kauri da abubuwa masu wuya kamar karfe da sassa na bakin karfe.

Don ƙananan ƙarfe ko kayan laushi kamar aluminum da sassa na filastik, riveting da shigar coils zai yi aiki mafi kyau.

2.Riving Nuts da Standoffs

Riveting ita ce hanya mafi sauƙi kuma mafi yawan amfani da ita wajen haɗuwa a sarrafa ƙarfe.

Riveting na iya samar da zaren tsayi da ƙarfi fiye da taɓa farantin ƙarfe na bakin ciki

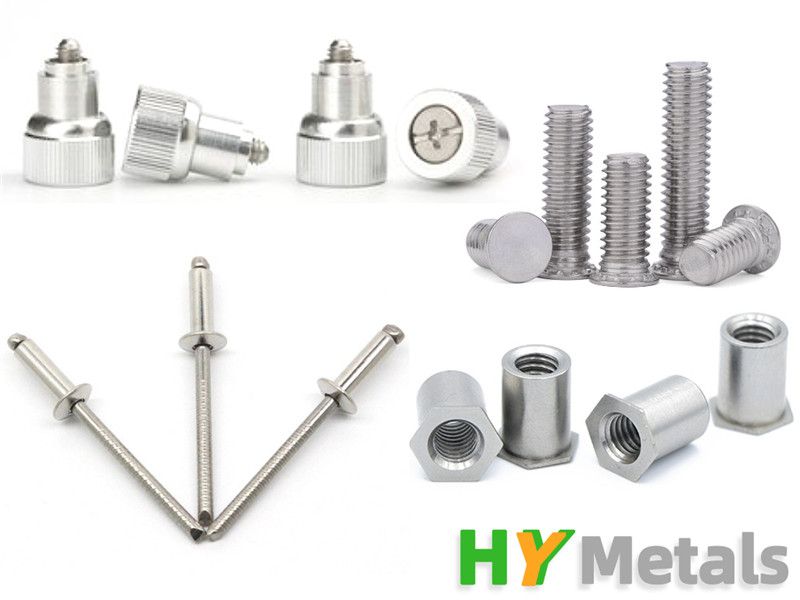

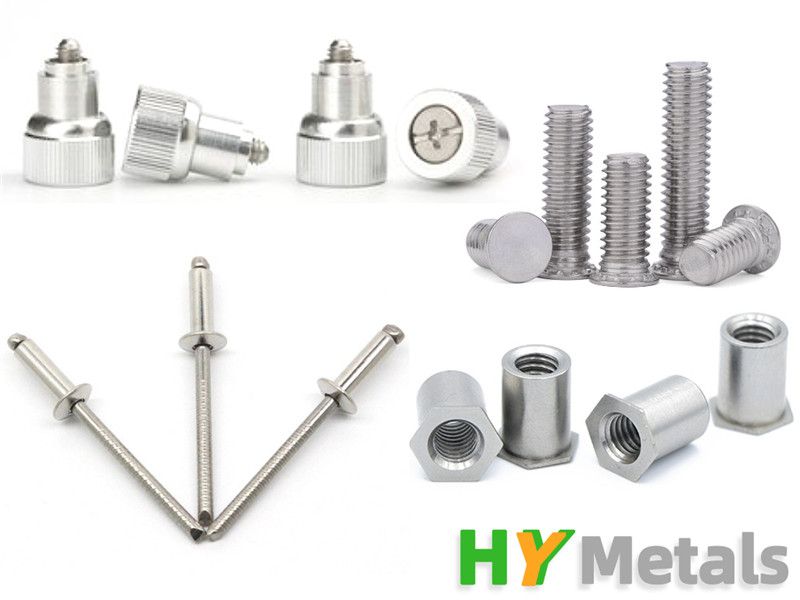

Akwai da yawa na Kwayoyi, sukurori da tsayawa ga riveting.Kuna iya samun duk daidaitaccen girman kayan aikin PEM da wasu kayan aikin MacMaster-Carr daga HY Metals don taron ku.

Don wasu kayan masarufi na musamman ba za mu iya samowa a cikin shagunan gida ba, zaku iya ba mu don haɗawa.

3. Shigar da shigarwar Heli-coil

Don wasu abubuwa masu kauri amma masu laushi kamar sassa na injin filastik, yawanci muna shigar da abubuwan da ake sakawa na Heli-coil a cikin ramukan injina don samun zaren taro.

Latsa Fit

Fitar da latsa ya dace da wasu fil da taro na shaft, kuma ana amfani da su sosai a sassan injinan, wani lokacin ana buƙata a ayyukan ƙarfe na takarda.

Walda

Welding wata hanyar haɗuwa ce da aka saba amfani da ita wajen kera ƙarfen takarda.Welding na iya sa sassa da yawa su haɗu tare da ƙarfi.

HY Metals na iya yin walda ta Laser, waldawar Argon-baka da waldawar baka na Carbon dioxide.

Dangane da matakin aikin walda na ƙarfe, an raba shi zuwa walda ta tabo, cikakken walda, walda mai hana ruwa.

Za mu iya biyan duk buƙatunku akan walda na ƙarfe don taron ku.

Wani lokaci, za mu goge alamun walda don samun fili mai santsi kafin shafa.