Daidaitaccen daidaitaccen CNC na'urorin Titanium tare da juyawa harbi

Wahala aCNCmachining da anodizing na Titanium gami sassa

Injin CNCna titanium gami yana ba da ƙayyadaddun ƙalubalen ƙalubale saboda abubuwan da ke tattare da kayan. Titanium sananne ne don girman ƙarfinsa-zuwa-nauyi, juriya na lalata, da daidaituwa, yana mai da shi mashahurin zaɓi don aikace-aikacen sararin samaniya, likitanci, da na kera. Koyaya, waɗannan halaye iri ɗaya kuma suna rikitar da aikin injin.

Kalubalen Gudanarwa

1. Kayan aiki:Titanium Alloys an san su zama abrasive, haddasawam kayan aiki lalacewa. Ƙarfin titanium yana nufin kayan aikin yankan dole ne a yi su daga kayan ci gaba kamar carbide ko yumbu don jure matsalolin da ke tattare da su. Ko da waɗannan kayan, rayuwar kayan aiki na iya zama gajarta sosai fiye da lokacin da ake sarrafa karafa masu laushi.

2. Zafi:Titanium yana da ƙarancin wutar lantarki, wanda ke nufin zafin da ake samu yayin sarrafawa baya bacewa da sauri. Wannan yana haifar da nakasar thermal na workpiece da yankan kayan aiki, wanda ke haifar da ƙarancin ƙarewar farfajiya da rashin daidaiton girma. Dabarun kwantar da hankali masu inganci, kamar yin amfani da tsarin sanyaya mai ƙarfi, suna da mahimmanci don rage wannan matsala.

3. Samuwar Chip:Yadda guntuwar titanium ke samuwa a lokacin injina shima yana iya haifar da matsala. Ba kamar karafa masu laushi waɗanda ke samar da kwakwalwan kwamfuta masu ci gaba ba, titanium yawanci yana samar da gajere, kwakwalwan kwamfuta masu kyau waɗanda za su iya haɗawa da kayan aiki ko kayan aiki, suna ƙara rikitar da aikin injin.

4. Ma'aunin injina:Zaɓin saurin yanke daidai, ƙimar ciyarwa da zurfin yanke yana da mahimmanci. Ma'auni waɗanda suke da ƙarfi na iya haifar da gazawar kayan aiki, yayin da saitunan da ke da ra'ayin mazan jiya na iya haifar da ingantacciyar mashin ɗin da ƙara lokacin samarwa. Neman ma'auni mafi kyau yana buƙatar ƙwarewa mai yawa da gwaji.

5. Rike kayan aiki:Titanium yana da ƙarancin elasticity na elasticity, wanda ke nufin zai lalata ƙarƙashin matsin lamba, yana sa kayan aiki yana riƙe da ƙalubale. Ana buƙatar gyare-gyare na musamman da hanyoyin matsewa sau da yawa don tabbatar da ɓangarorin sun tsaya tsayin daka yayin aikin injin, wanda zai iya ƙara rikitarwa da tsada ga aikin.

Kalubalen Anodizing

BayanCNCmachining ne cikakke, anodizing da titanium gami kara dagula tsarin masana'antu.Anodizingtsari ne na lantarki wanda ke haɓaka juriya na lalata kuma yana ba da kyakkyawan gamawa. Koyaya, anodizing titanium yana zuwa tare da nasa matsalolin.

1. Shirye-shiryen Sama:Dole ne a shirya farfajiyar titanium a hankali kafin anodizing. Duk wani gurɓataccen abu, kamar mai ko sauran abubuwan sarrafawa, na iya haifar da ƙarancin mannewar Layer na anodized. Wannan sau da yawa yana buƙatar ƙarin hanyoyin tsaftacewa, kamar tsaftacewa na ultrasonic ko etching sinadaran, wanda ke ƙara yawan lokacin samarwa da farashi.

2. Anodizing tsari kula:Tsarin anodizing na titanium yana kula da sigogi daban-daban, gami da ƙarfin lantarki, zafin jiki da abun da ke ciki na lantarki. Samun nau'in nau'in anodized Layer yana buƙatar daidaitaccen sarrafa waɗannan masu canji. Bambance-bambance na iya haifar da rashin daidaituwa da launi da kauri, wanda ba a yarda da shi ba a cikin aikace-aikace masu mahimmanci.

3. Daidaiton Launi:Anodized titanium iya samar da kewayon launuka dangane da kauri daga cikin anodized Layer. Koyaya, samun daidaiton launi a cikin sassa da yawa na iya zama ƙalubale saboda bambance-bambancen ƙarewar saman da kauri. Wannan rashin daidaituwa na iya zama matsala ga aikace-aikace inda daidaiton ado yana da mahimmanci.

4. Maganin bayan anodizing:Bayan anodizing, ana iya buƙatar ƙarin jiyya don haɓaka aikin Layer na anodized. Waɗannan na iya haɗawa da hanyoyin rufewa, wanda zai iya ƙara dagula aikin aiki da haɓaka lokacin samarwa.

A karshe

CNC machining da m anodizing na titanium alloys ne hadaddun tafiyar matakai da bukatar musamman ilimi, kayan aiki da fasaha. Kalubalen da ke da alaƙa da injina, kamar lalacewa na kayan aiki, samar da zafi da samuwar guntu, haɗe tare da rikitattun abubuwan anodizing, suna jaddada buƙatar yin shiri da aiwatar da hankali. Kamar yadda buƙatun kayan aikin titanium masu girma ke ci gaba da karuwa a cikin masana'antu, shawo kan waɗannan matsalolin yana da mahimmanci ga masana'antun da ke da niyyar cimma ingantacciyar inganci da ƙa'idodin aiki.

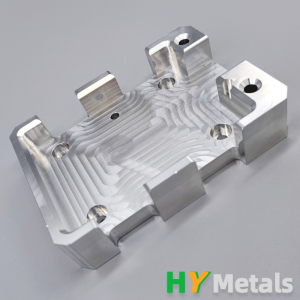

HY Metals kwararre ne a cikin injina na CNC tare da gogewar shekaru sama da 14, mun ƙera ɓangarorin Titanium da yawa tare da madaidaicin inganci da inganci.

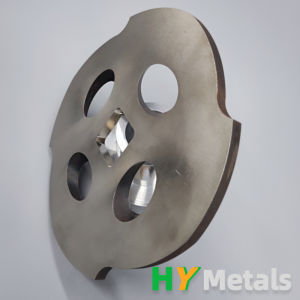

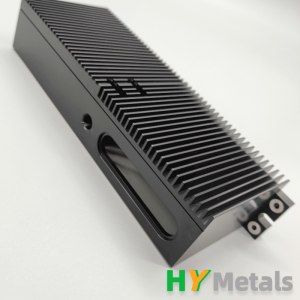

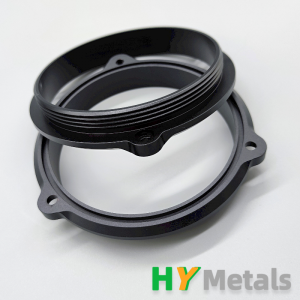

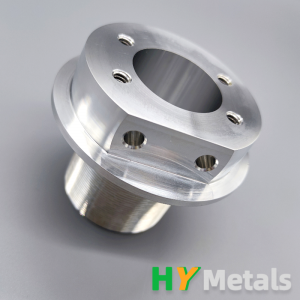

Ga wasu sabbin masu shigowa naCNC kayan aikin TitaniumKamfanin HY Metals.

HY Karfebayar datsayawa dayasabis na masana'anta na al'ada ciki har dazane karfe ƙirƙira kumaInjin CNC, shekaru 14 gwaninta da8 cikakken kayan aiki.

Madallaingancisarrafawa,gajerejuyawa,mai girmasadarwa.

Aika RFQ ɗinku dacikakken zane-zaneyau. Za mu kawo muku ASAP.

WeChat:na 09260838

Fada:+86 15815874097

Imel:susanx@hymetalproducts.com